Downtime in productions is a costly affair and should be avoided. Do you know how?

Minimizing production downtime is crucial and requires strategic measures. Be aware of these 4 effective strategies.

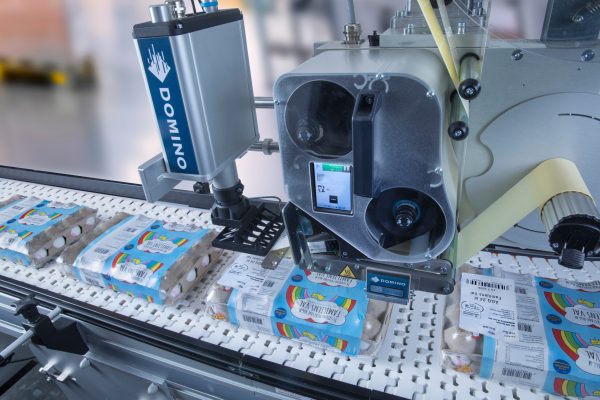

Ensure Printer Resilience:

Protect printers in challenging environments by choosing those with a high IP rating. Daily washdowns require a robust printer that can withstand harsh conditions. Opt for stainless steel cabinets, particularly ASIS 316, for optimal corrosion resistance, enhancing overall durability.

Minimize Coding Errors:

Reduce downtime by limiting direct inputs on the printer and relocating label template design to authorized personnel via software on an office PC. Integrate printers with MES and ERP systems to eliminate human errors and automate code handling with minimal manual intervention.

Optimize Print Functionality:

Achieve clear codes by optimizing both printer and ink. Imperfect ink droplet formation can result in unclear codes. Choose advanced Continuous Inkjet printers (CIJ) with precise printheads for consistent, high-speed, and reliable code quality.

Duo System Efficiency:

Meet two-line code demands without compromising production speed or investing in two printers. Opt for a CIJ printer with a duo system, providing the same functionality as two printers without additional costs, ongoing maintenance, and associated downtime. Duo systems print two-line codes twice as fast as single inkjet systems, allowing manufacturers to maximize earnings.